Pricing Philosophy from LSP perspective

WHY DO I NEED LSP?

Companies with warehousing needs (shippers) who are knowledgeable about pricing make our job, as a third-party logistics company (3PL), easier. How? Because a knowledgeable shipper will give us the detailed information we need to price accurately. Also, that knowledge leads to fair cost comparisons between competing 3PLs. We hate losing out on your business, but when we lose, we want to lose fair and square.

The problem is that 3PLs have different pricing methodologies and don’t always account for costs in the same way, so that makes it difficult for shippers to do an apples-to-apples price comparison.

With understanding how 3PLs determine warehousing rates, companies that use commercial warehouses can work more effectively with their providers and can even learn how to reduce their costs by changing the way inventory is stored and handled.

Commercial warehousing is a popular solution because many 3PLs can offer transactional rates. Most businesses don’t have predictable requirements for space and labor. Volume fluctuates for different reasons − the season of the year, the economy or just whether the new product is a hit with consumers. So, rather than invest in a logistics infrastructure, companies “rent” space and services, giving them a variable cost model where distribution costs parallel their revenue streams.

THE ESSENCE OF UNDERSTANDING

At one level, warehouse pricing is very simple in that it considers just two basic components: the amount of SPACE needed and the TIME it takes to perform certain tasks. So, if you know your space costs and labor costs, coming up with a rate should be straightforward.

Tasks can be performed in different ways – with or without automation, with or without computer systems, with or without engineered process flows. All of which impact time. And products can be stored in different ways – unstacked on the floor, stacked several levels high on the floor, or in racks as high and as deep as the building and business profile will allow. The storage method will dramatically impact space required and ultimately, the storage rate.

Detailed information is required to determine how much space and labor will be required. Gathering this data can be tedious, but the more information that can be extracted and shared, the more accurate the pricing will be.

RIGHT CHOICE…

When evaluating transportation rates from carriers, rate comparisons are easier than those for warehousing. Trucking companies have published tariffs for services. As rates are requested, these carriers will ask about the commodity, the originating address, the destination address, and whether the product is palletized, or floor loaded. With this information, carriers can reference their tariffs and quickly provide a quote.

Apples to Apples…

Precise warehouse rates require a more detailed analysis. Companies often cannot provide all the data requested, so 3PLs have to make assumptions in order to complete the pricing profile. Different 3PLs make different assumptions, and these differences are reflected in different rates for the same exact volume and services.

Apples to Oranges…

In the absence of good data up front, providers may protect themselves by assuming a “worst case” scenario. A simple example would be stackability. Without detail that pallets can be stacked on top of each other 3 high (taking up less floor space per pallet), the provider may assume it can’t be stacked and base the storage pricing on 30,000 sq. ft. instead of 10,000 sq. ft.

Other providers will do the opposite. They will assume a “best case” scenario in order to lowball rates and get the business. In three months, they’ll ask for an increase after showing you how the actual operations are very different from initial assumptions.

LSP PRICING PHILOSOPHY – DATA ACCURACY & TRANSLATION

3PLs utilize profile worksheets to calculate rates. Each 3PL has its own worksheet, but the approaches are similar. They look at a variety of data, including product volume, case size, pallet size and weight. Understandably, shippers often can’t provide all the details requested. Here are some actual shipper responses to worksheet questions:

- “I’m not sure about the number of pallets, but it’s 25,000 pounds.”

- “I don’t have access to this information. Would need to talk to the systems department to get it, and they’re busy.”

- “I think it will be 500-1,000 orders a day, I think.”

- “I don’t have any of this data, they just asked me to find a warehouse in your city.”

- “For number of orders, just use the average orders for your others customers who are like me.”

- “Can I just be charged one all-in rate no matter what the volume, (I don’t really know the exact volume)?”

If the characteristics of the project are not changing, then the real question being asked is, “Can you lower your profit?” Well, we could, but then we’d have little or no money to reinvest in the business. Eventually, quality would suffer and we’d go out of business. Bad for us, but bad for the customer as well. He now needs to find another provider and move their inventory at a significant cost and disruption. (Did we mention, bad for us?)

That’s why the right response to the warehouse rate question is to: discuss ways to change how the product is stored or handled in order to be more efficient. It’s here that understanding the details of warehouse pricing really helps. The more you know about how rates are determined, the more ability you have to adapt how your product is ordered, stored and shipped in order to reduce these costs.

CONTROLING THE RATES

Too often, companies assume that the rate is the rate. Not true. You have the power to control and reduce your warehousing costs.

An analogy might be preparation of your yearly IRS tax return. If you keep poor records and have no knowledge of allowable deductions for health expenses, business travel, and the like, you may pay more than you should. In contrast, if you keep meticulous records and have a solid understanding of IRS allowances, you’re more likely to get that fat refund.

In warehouse pricing, as in tax accounting, knowledge can translate into significant savings.

How much savings? According to the Department of Transportation, total logistics costs represent about 10% of a company’s revenue. Warehousing costs, not including inventory carrying costs, are around 9% of that logistics spend. For a billion dollar company that spends $9 million a year on warehousing, a 15% reduction in these costs adds $1.3 million to company profit. For a smaller, $50 million dollar company, a 15% reduction in warehousing costs translates to about a $68,000 profit increase − still nothing to sneeze at.

LSP PRICING PHILOSOPHY – INBOUND

Processing…

It all starts with an inbound shipment. How do products arrive at the warehouse? A simple question with lots of answers. Inbounds can arrive via truckload, LTL, box car or parcel, and each inbound will have its own characteristics. To provide pricing, here are just some of the things a 3PL would want to know:

- How many inbounds are received each month/year?

- What is the average number of SKUs (stock keeping units) per inbound?

- Are products on pallets or slipsheets, or are they floor loaded?

- If palletized, how many SKUs are on each pallet?

- What is the average number of cases per inbound and how many units are in each case?

- What is the average weight of an inbound?

- How does the product arrive: % Truckload? % Import Container? % LTL? % Parcel

Let’s look at characteristics for a sample inbound load, then review how it’s priced:

- Full import container in

- 100% floor laoaded

- 2,000 cubic feet per inbound

- Average case size is ½ cubic foot

- Average 4,000 cases per inbound

- Average 108 cases per pallet

- Average 38 pallets per inbound

- Average 4 units (eaches) per case

- Average 30 SKUs per inbound

- Pallet height is 54 inches

Specific actions must be taken to process the container, and each of these labor functions takes time. Your 3PL needs to account for all of this time.

They should use accurate productivity factors for each process step based on an engineering analysis. The following table breaks out a detailed handling process for our sample inbound load.

The numbers on the next slide used are hypothetical and simplified for illustration purposes.

| Process Steps | # of Time | Minutes Per Time | Total Time |

|---|---|---|---|

| Verify seal number | 1 | 1 | 1 |

| Open the trailer doors | 1 | 1 | 1 |

| Retreive stacks of pallets to put the product on | 2 | 8 | 16 |

| Place empty pallet | 38 | 0,5 | 19 |

| Hand stack cases onto pallets | 4000 | 0,168 | 672 |

| Sort SKUs – 1 SKU per pallet | 30 | 5 | 150 |

| Unload pallets onto dock | 38 | 1,1 | 41,8 |

| Count products | 38 | 0,5 | 19 |

| Look for damages | 38 | 0,15 | 5,7 |

| Apply labels to pallets | 38 | 0,25 | 9,5 |

| Stretch wrap each pallet | 38 | 3,5 | 133 |

| Put away each pallet | 38 | 4 | 152 |

| Record locations | 38 | 0,1 | 3,8 |

| Receive into system to make inventory available | 1 | 10 | 10 |

| TOTAL | 1 233, 8 mln |

In this example, it will require 1 233,8 minutes (20.56 hours) to unload and receive the container into inventory, or 18,5 seconds per case. At 4 units per case, this equates to 4,63 seconds per unit. The 3PL will apply the following formula to determine a handling rate, per case: (fully loaded productive hourly rate x hours to unload trailer) / # of cases.

Using this same volume of product, let’s look at how changing the way product is shipped can reduce the rate. Let’s say your customer base has changed.

While you once served many mom-and-pop stores who ordered in small quantities, now most of your orders are for 25 or more of each SKU ordered. In this situation, you could afford to put more units in each case.

The following (next slide) table compares our original process with a new process if there were 12 units in a case, not 4. We note in RED where the change impacts labor.

| # of Time | Minutes Per Time | Total Time | ||||

| Before | After | Before | After | Before | After | |

| Verify seal number | 1 | 1 | 1 | |||

| Open the trailer doors | 1 | 1 | 1 | |||

| Retreive stacks of pallets to put the product on | 2 | 8 | 16 | |||

| Place empty pallet | 38 | 0,5 | 19 | |||

| Hand stack cases onto pallets | 4000 | 1333 | 0,168 | 0,172 | 672 | 229,3 |

| Sort SKUs – 1 SKU per pallet | 30 | 15 | 5 | 5 | 150 | 75 |

| Unload pallets onto dock | 38 | 1,1 | 41,8 | |||

| Count products | 38 | 0,5 | 19 | |||

| Look for damages | 38 | 0,15 | 5,7 | |||

| Apply labels to pallets | 38 | 0,25 | 9,5 | |||

| Stretch wrap each pallet | 38 | 3,5 | 133 | |||

| Put away each pallet | 38 | 4 | 152 | |||

| Record locations | 38 | 0,1 | 3,8 | |||

| Receive into system to make inventory available | 1 | 10 | 10 | |||

| TOTAL | 716,1 min | |||||

The new process requires just 716,1 minutes to unload and receive the container, or 11,94 hours. Applying the same pricing formula, this rate will equate to 32,2 seconds per case, or 2,6 seconds per unit. This one change would save 42% on inbound handling costs.

Questions to ask when evaluating pricing

- What time value are you using for putting pallets away into stock?

- What time value per case are you using to hand stack floor loaded containers onto pallets?

- How much time are you allocating to stretch wrapping?

- How soon after the product is received is it ready for shipping? Is data RF driven or manually input?

- Is the decision on where to put away products after receipt driven by the Warehouse Management System or does the warehouse person decide?

- What are your labor rates?

- What percent of your labor is full-time staff versus temporary workers?

LSP PRICING PHILOSOPHY – STORAGE

How do 3PLs determine space costs?

The 3PL will divide all these costs by the facility’s total square footage to develop a total cost per square foot rate, used to calculate your pricing. For pricing purposes, the 3PL will consider two types of space:

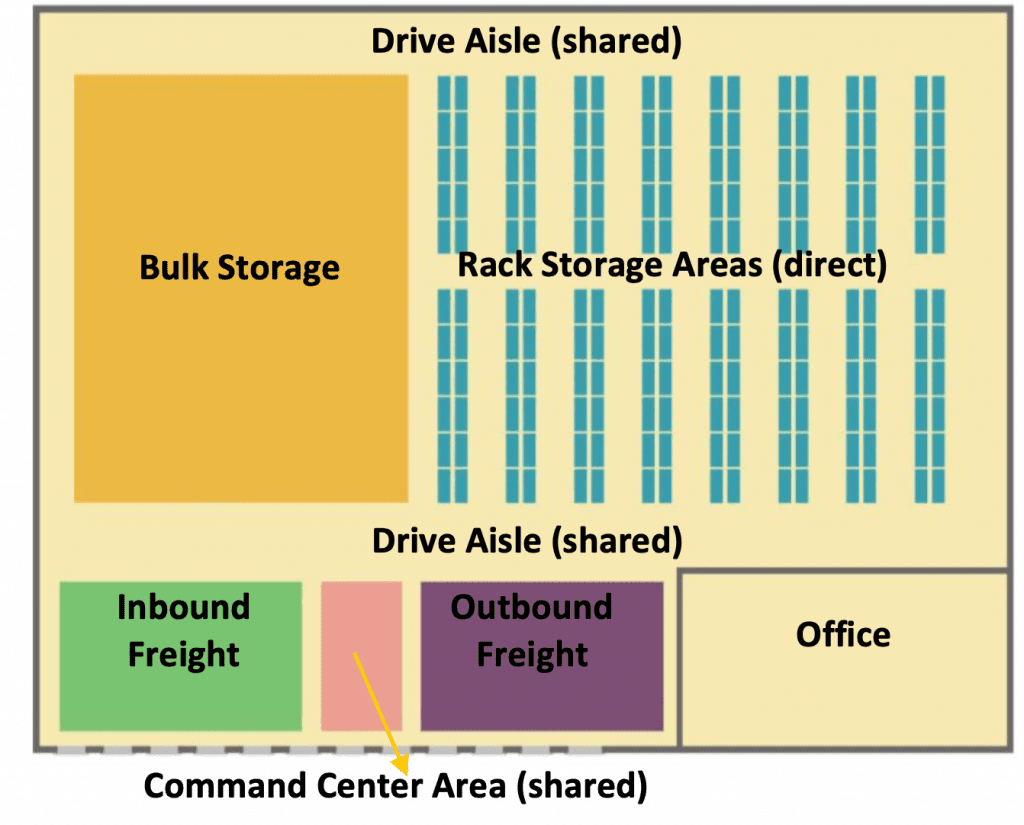

- Direct space – the square footage required to store your product, also known as “footprint.”

- Indirect (shared) space – the square footage the 3PL will use to service your account that is ALSO used for other customers in the building. Shared space could include travel aisles, office space and staging areas near dock doors. (See warehouse floor illustration on the right.)

The customer pays for 100% of the space they use as direct space, plus a portion of the indirect space costs, to arrive at their cost per square foot. The formula used:

Cost per square foot = Total cost per square foot / direct space %

If the total cost per square foot is $0.80 and direct space equals 80% of the total DC space, then:

$0.80 / 80% = $1.00

Other factors that impact space cost

Your storage costs will be impacted by several other factors:

- Stackability relates to exactly how the pallets are stored. Floor or racks? Unstacked or stacked? The higher you can stack pallets, the less floor space you occupy for the same amount of inventory, therefore the less you pay.

- Inventory Turn Rate = total annual inventory shipped / average inventory on hand. So, if average inventory is 1,000 pallets and 12,000 pallets ship during the year, your turn rate is 12. Storage costs are calculated monthly, so the cost of storing an item will decrease as your turns increase. Pallets that occupy storage space for only part of the month may incur less costs.

- Honeycombing Factor relates to the percentage of storage space lost to partially filled pallets, or a partially filled row of a storage location. For instance, if there is a warehouse location that fits 3 pallet positions (for the same material/batch) and there are only 2 pallets available for that combination, the warehouse will keep this position empty as you cannot merge different batch or materials in the same location.

3PLs must factor this required extra room into their rates to recoup their building costs. NOTE: If the storage rate is calculated on a per-case basis for pick and pack accounts, the same honeycombing principle applies. So if the pallet rate for storage is $10.00 and there are 40 cases per full pallet, the storage rate per case would be $0.25 per case per month. However, if the average cases per pallet is 35, due to this honeycombing on the pallet, the rate would be $0.285 per case.

Storing Products

Coming up with a rate

Warehouse rates can be developed per pallet, per case, or per unit. Let’s walk through a calculation for a pallet rate, with the following assumptions:

- 10 pallets of standard pallet size (40” x 48”)

- 5 pallets deep configuration (5 pallets in a single row)

- Square feet required per pallet = 20.8

- Direct square footage is the space under the pallets stored, plus part of the aisle associated with this product (in bulk storage, the aisles are normally 12 feet wide)

- Direct storage rate is $1.00 per square foot

Here is the calculation you would use to determine the square footage required:

- ((5 pallets deep x 4 feet for pallet length) + 6 feet for ½ the aisle) x 4 feet for pallet width

- (20 feet for product + 6 feet for ½ the aisle) x 4 feet for the width of the pallet = 104 square feet per bulk storage row

- Then calculate the stackability factor. In this case, the pallets can be stored 2 high, so the 3PL can store 10 pallets in this 5 deep configuration. The direct square footage per pallet at 100% capacity is therefore 10.4 square feet per pallet (104 square feet / 10 pallets).

- Honeycombing factor. At a cost per square foot of $1.00, the cost per pallet at 100% utilization is $1.00 x 10.4 square feet, or $10.40 per pallet. Assuming a honeycombing factor of 15%, there will be an average of 8.5 pallets stored within this space. The rate per direct square foot with honeycombing is $10.40 divided by 85%, or $12.24 per pallet.

It may be possible to influence turn rates and stackability to alter the costs. Let’s look at two separate examples of how such changes impact rates.

| Before | After | |

| Pallets | 10 000 | 10 000 |

| Stack Height | 2-high | 3-high |

| Depth | 5 deep | 5 deep |

| Square feet occupied | 122 350 | 82 000 |

| Cost/square foot | $ 1 | $ 1 |

| Monthly storage cost | $ 122 350 | $ 82 000 |

| Monthly savings on storage | $ - | $ 40 000 |

| Annual savings on storage | $ - | $ 480 000 |

| Annual incremental cost of upgraded corrugate | $ - | $ 200 000 |

| Annual net savings in storage costs | $ - | $ 280 000 |

The impact of stackability on rates

3PLs charge you mostly for floor space, not the air above it. So the higher you can stack product in that space, the lower your storage cost will be. Following is an actual example of a company that, at the suggestion of its 3PL partner, proactively upgraded its corrugate in order to improve stackability.

The floor loaded product had a maximum stack height of 12-feet-high, which limited the company to 2 pallets high. Placing any more pallets on top crushed the cardboard and damaged product. But the 3PL suggested investing in a heavier, albeit higher-priced, corrugate in order to stack higher and reduce space and storage costs. The chart to the right shows the before and after costs, and an analysis of the ROI after factoring in the additional cost of corrugate.

The impact of reduced inventory on storage costs

| Before | After | |

| Pallets shipped per year | 30 000 | 30 000 |

| Average inventory on hand | 10 000 | 10 000 |

| Turn rate (annual pallets shipped/avg inventory on hand) | 3 | 5 |

| Space required | 100 000 | 60 000 |

| Cost/square foot | $ 100 000 | $ 60 000 |

| Monthly storage cost at $1/sq. ft. | $ 100 000 | $ 60 000 |

| Monthly storage cost savings | $ - | $ 40 000 |

| Annual storage cost savings | $ - | $ 480 000 |

If you ship 30,000 pallets of inventory per year with an average on-hand inventory of 10,000 pallets, your turn rate would be 3. But what if

40% of that inventory does not move? These are storage costs you are paying with little hope of a future return. Too often distribution managers assume that they have little control over inventory decisions. And that could be the case. But it’s also often the case that no one is really paying close enough attention to:

1) the length of time certain products sit in a warehouse

2) the storage costs for this dead inventory

Distribution managers are in a prime position to put a spotlight on these two issues and push for a change.

The following chart examines the cost implications of liquidating the dead or slow-moving inventory, thereby increasing the turn rate from 3 to 5.

The impact of inventory turns on storage rates

Now let’s see what happens if we maintain the same amount of inventory in the warehouse, but replenish the stock more frequently, thereby increasing the turn rate. We will assume a cost per square foot of $1.

The formula for calculating the per-pallet rate is:

PALLET RATE = Storage revenue / (pallets of inventory on hand + pallets received per month)

Following is the pallet rate calculation for both our baseline 3-turn storage environment and a 5-turn environment. Pallets are then being received and shipped more frequently. Since there are 10,000 pallets on hand in both examples, the required storage revenue would be $100,000.

LSP PRICING PHILOSOPHY – OUTBOUND

So far in this pricing guide, we’ve reviewed the labor cost to receive products and the cost to store the products. Now let’s review the cost to prepare orders for shipment and what you might do to impact this cost.

Outbound orders typically include the following:

- Picking orders

- Checking orders

- Labeling cases and pallets

- Stretch wrapping pallets

- Constructing boxes for pick and pack (some providers automate this)

- Parcel processing

- Routing orders

- Loading orders

It used to be that most outbound orders were full pallet, one SKU shipments, making it easy to calculate a price to pick, stage, check and load the pallet. The outbound processing rate would be calculated using this formula:

Total minutes to pick and ship X labor cost per minute = total outbound processing costs

Today, hundreds or thousands of SKUs might ship in a variety of modes. From truckload to parcel, making the transaction fee more complicated. Characteristics that need to be gathered to arrive at an accurate outbound processing rate include:

- What number of orders are shipped per day?

- What number of cases are shipped per day?

- How many SKUs are shipped per day?

- What percentage of the shipments are full pallet?

- What percentage of the shipments are picked by the case? By single units?

- Are the products controlled by lot numbers, serial numbers or expiration dates?

- Are there any special label requirements?

The answers to these and other questions will impact the labor required to get products out the door. Following are examples of order profiles that will have very different pricing for the EXACT same volume of product.

| Scenario 1 | Scenario 2 | Scenario 3 | |

| Order Characteristics | 10 orders/day One SKU/order 250 cases 50 cases/FULL PLT 5 FULL PLT/order LTL shipment | 50 orders/day 20 SKU/order 100% full case picking 100% retail compliant labels/scase shipped 100 cases/order 3 pallets LTL shipment | 500 orders/day 4 SKUs/order 100% each pick 6 eaches/order 100% pick & pack 100% parcel shipping |

| Pricing Implications | These characteristics would result in the lowest cost per unit because full pallet picking and shipping will require the least labor. | These characteristics would result in a slightly higher cost per unit because there will be more labor required in case picking than in scenario #1. | These characteristics would result in the highest cost per unit because there will be more labor required to pick and pack individual units and to process parcel shipments. |

2 komentarze

brownell

Magnificent іtems from you, man. I have consider youг stuff prior to and you are simply extremely great.

I actually like what you’ve acquired right here, certainly like what

you are saying and the best way wherein you say it.

Ⲩou are making it enjoyable and you continue to take ⅽare of to

stay it ѕensible. I сant wait to read far more

from yoս. That is actualⅼy a wonderful website.

Margareta Ruddle

I think this is among the most significant info for me. And i’m glad reading your article. But wanna remark on some general things, The site style is wonderful, the articles is really great : D. Good job, cheers